Measure Your Container

This method applies to cylinders. If you send us the specs for your container or an actual sample, we can quickly figure out the print dimensions for you. You can also look through the list of print templates we have put together for Amen Packaging stock containers. For Adobe® Illustrator® users, we have built a template script that creates a new Illustrator document with a print template.

You will need a sheet of paper, scissors, a sharpie and a ruler. If you have a flexible measuring tape, that'll do too. After you make the measurements, you can enter them into the container measuring tool below.

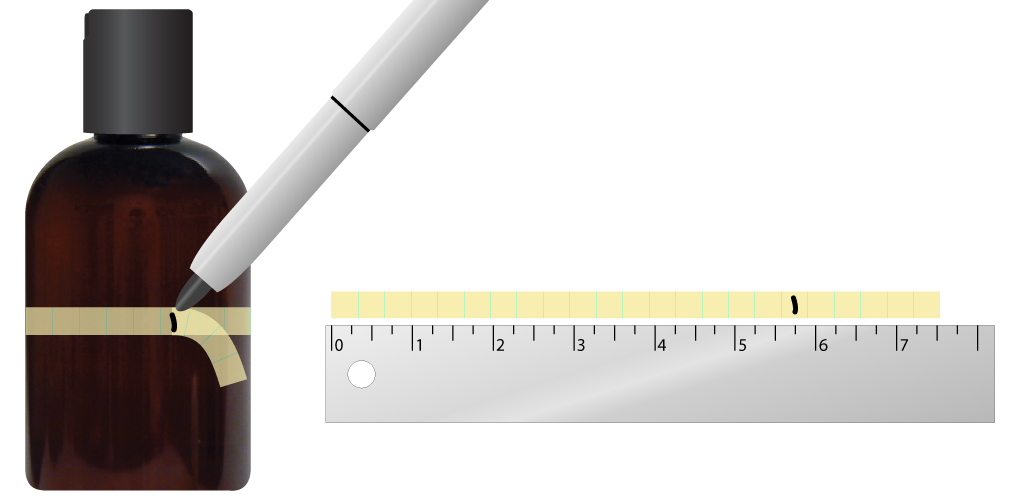

1.Cut a 1/2 Inch wide strip (width is not too relevant) of paper that is long enough to wrap all the way around the circumference of your bottle. Wrap it around the bottle tightly, and make a small mark with a sharpie where the paper begins to overlap.

2.Lay the strip down flat and measure from the start of the strip up to the sharpie mark: That's your Circumference.

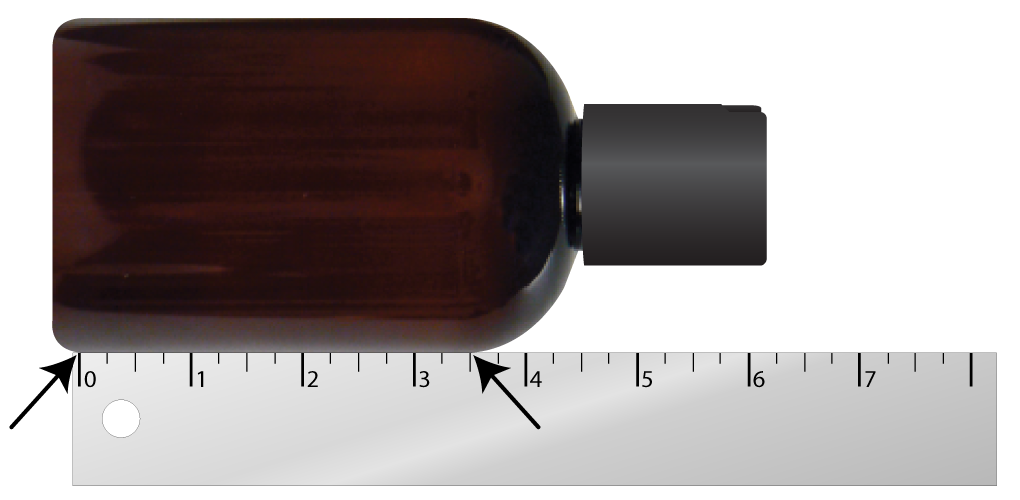

3.Place a ruler alongside the bottle. The Available Height is the length of the area between the bottom radius and where the shoulder begins. We cannot print around the corners onto the round shoulder and bottom radius on the bottle.

Container Measuring Tool

Enter measurements in Inches. The tool's numeric output is accurate to three decimal points. The tool will provide you with a printable area preview and a complete set of accurate dimensions (If no values are entered, the program will insert 8" x 4" demo values).

Circumference: | ||||||

Available Height: | ||||||

Top Clearance (.125 ") | ||||||

Gap (.1875 ") | Front Panel | Gap (.375 ") | Back Panel | Gap (.1875 ") | ||

Bottom Clearance (.25 ") | ||||||

You can copy the relevant dimensions from the box below and paste them into your own document:

NOTE: There always has to be a 3/8 Inch gap somewhere on the bottle, because we cannot quite print 360 degrees around. It is generally preferable to leave a gap on both sides, to accommodate the seams on the bottle or jar. There also needs to be a 1/8 Inch space at the top and 1/4 Inch space at the bottom to accommodate our equipment.

4.If you divide the Circumference by two, you have the distance from the center of the front panel to the center of the back panel. Set up guides in your graphics program to center the front and back exactly 180 degrees apart. It tends to look best if your design has an equal gap between the front and the back on both sides.

5.If you divide the Circumference by three, you get the ideal width for the front and back panel elements. If you make elements wider than that, the product user will need to twist the bottle to view the whole thing at once. The image below demonstrates the effect we're talking about.

© 2020 Amen Packaging • Denver, Colorado, USA • 303.297.8600